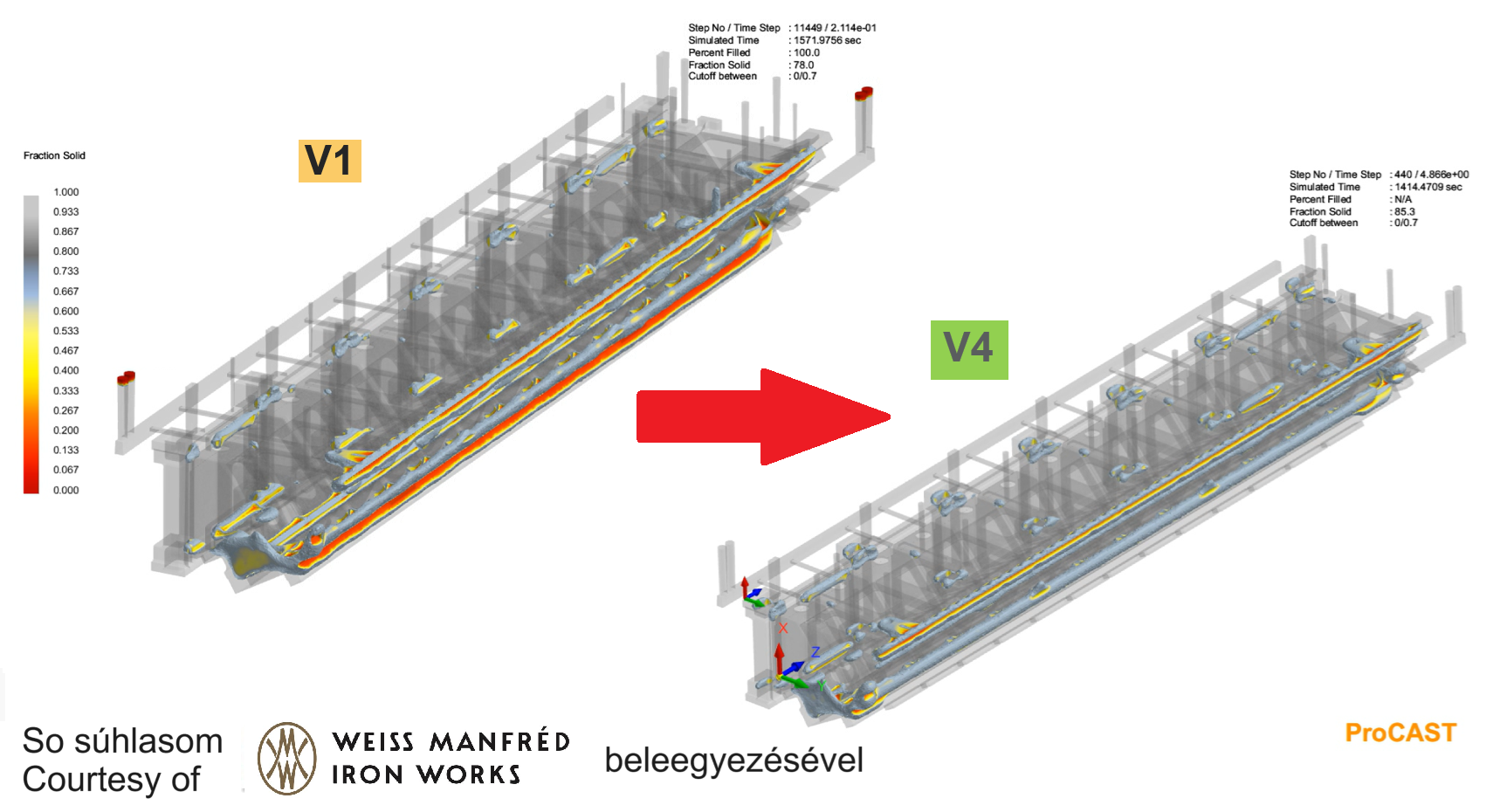

Verification of the production technology plan of the 5-meter machine tool bed

The customer entrusted us with the verification of the production technology plan of the 5-meter machine tool bed. After removal from the mold, the casting showed excessive deformations, which made it impossible to machine it within the prescribed tolerances. Our task was to make changes that, after removal from the mold and cooling, showed deformations within the required tolerance field. In cooperation with the manufacturer, we implemented 3 different production technology modifications, at the end of which the goals set by the customer were achieved. Thanks to these unique versions, we not only improved the production of the given part, but the customer gained additional information about the processes of the casting during solidification and after removal from the mold, which can be used in the design of larger, similar parts. sizes, which gives them a competitive advantage. The development task was carried out between July and August 2024 and was completed at TRL7 level having carried out all prototype tests on a digital prototype, including he necessary verification tests on real prototypes. The funding for this development task was provided by the client and copyright owner, WEISS MANFRÉD VASMŰVEK Kft.