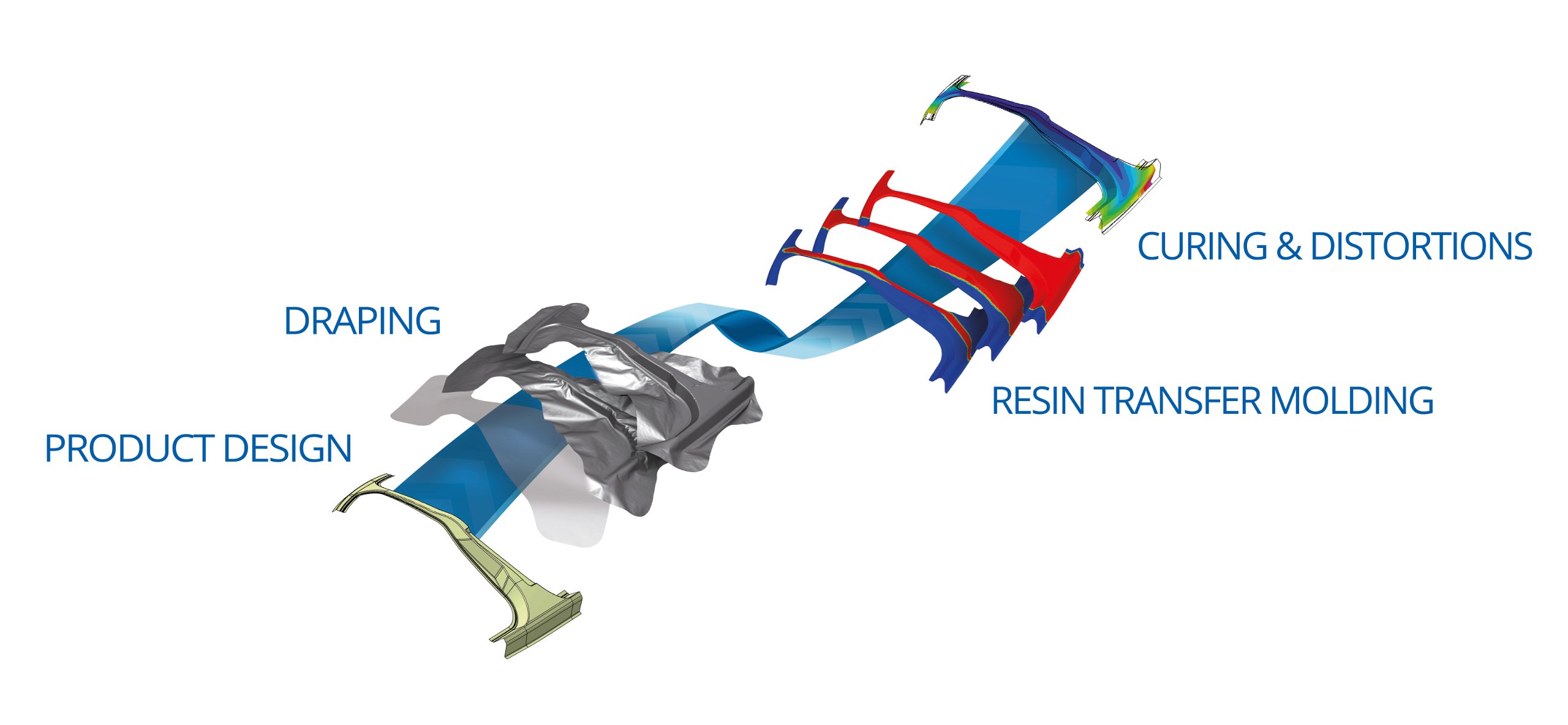

Prevent and correct manufacturing defects of composite structural parts

PAM-COMPOSITES allows you to define and optimize the process parameters to minimize manufacturing defects and increase final product quality, taking into account each step of the manufacturing chain.

PAM-COMPOSITES is a unique suite of Finite Element simulation tools dedicated to the manufacturing of composite parts made of continuous fibers - carbon, glass or natural fibers; unidirectional, woven or non-crimp-fabric - and a thermoset or thermoplastic matrix.

Main Applications

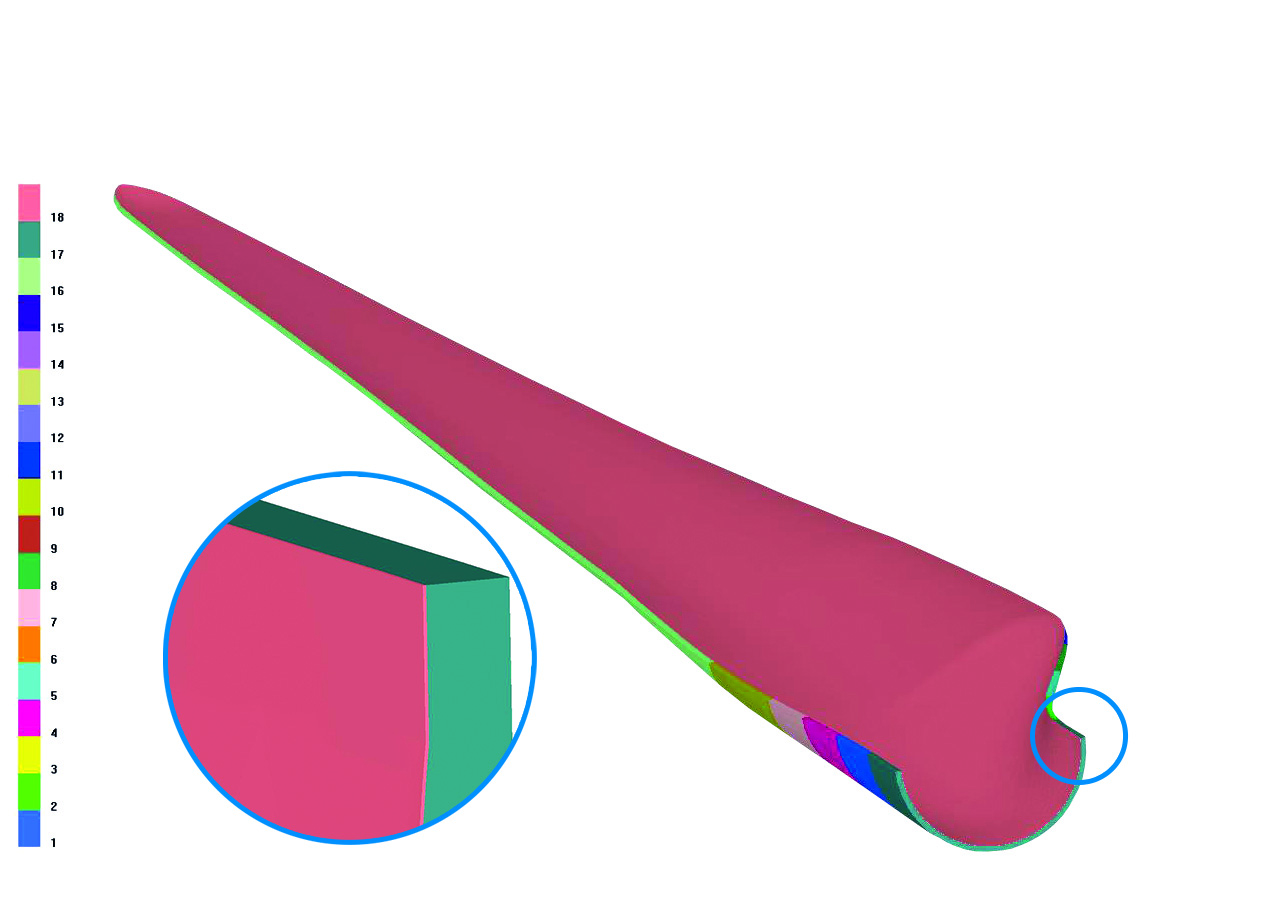

- Draping of dry textiles

- Thermoforming of thermoset or thermoplastic prepregs

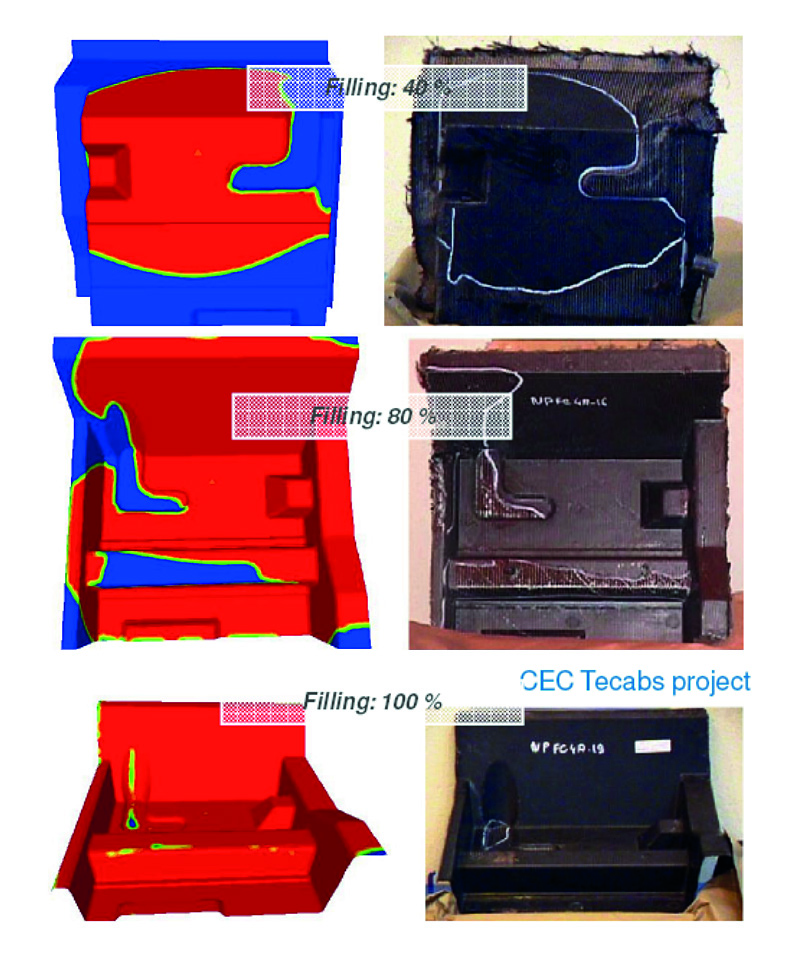

- Liquid Composites Molding - infusion or injection in a preform

- Curing of thermoset composite materials

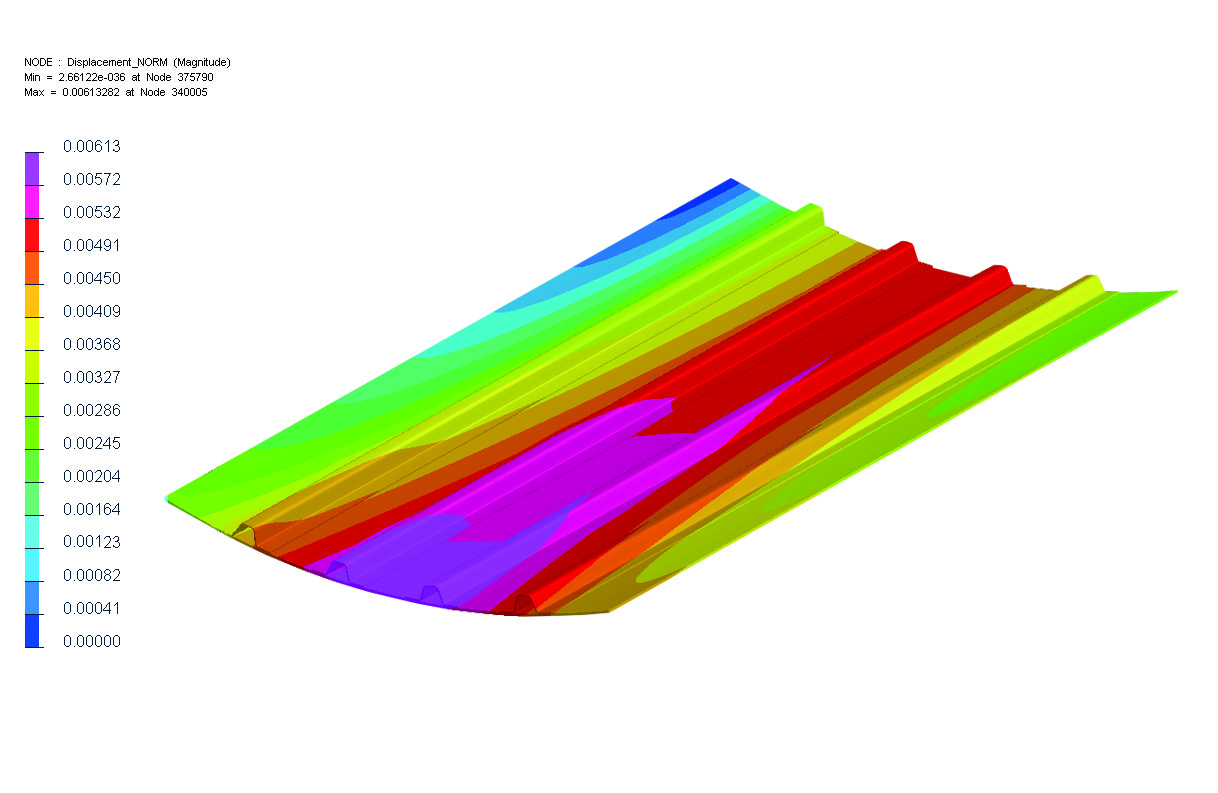

- Computation of Residual stresses and geometrical distortions induced by curing

Each step of the manufacturing process is simulated and analyzed. Then, material information and history, such as shearing, temperature and degree of cure, are transmitted from one stage of the process to the next.

Towards a Product/Process Design Approach

Manufacturing results can then be transferred to static or dynamic structural analysis to realistically simulate the product “as-built” as opposed to “as-designed”. Thanks to this product/process design approach, design margins are minimized and weight reduction is pushed further.

A Pam-Composites Szoftvercsomag felépítése

Draping and Thermoforming

Liquid Composites Molding (LCM)

Curing and Distortions

Ready for a license?

Looking for more information?